Belt weighers & scales: W&M approved weighing indicators

Robust. Flexible. Efficient.

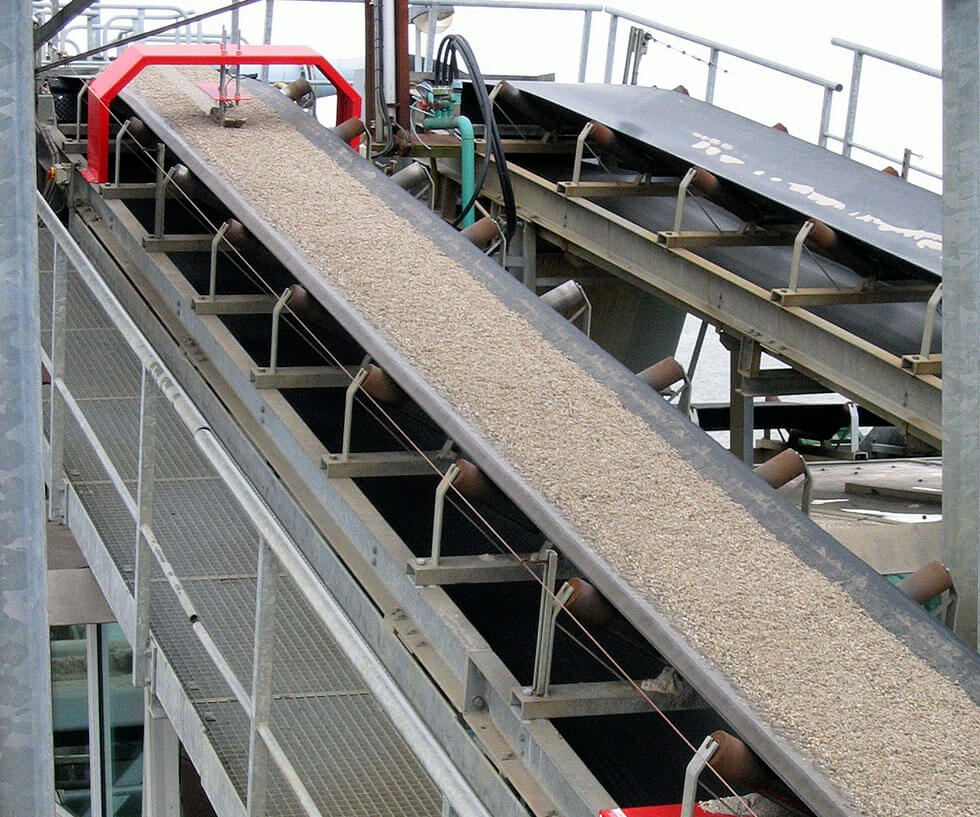

Belt weighers: SysTec weighing indicators have proven effective for dynamic weight capturing and batching of bulk material in harsh industrial environments. The SysTec weighing electronics connect to a belt scale structure with one or several analog load cells. Simple belt weighers only register the quantitative throughput; the batching mode however allows to adapt the belt speed in order to maintain a set target flow rate. SysTec weighing indicators operate in combination with a PLC, a SCADA system or as stand-alone entity. We are constantly integrating new features into our products - such as dynamic tilt compensation for the BELT E software.

Which weighing indicator fits best your belt scales?

7 good reasons for SysTec belt scale controllers

- Capturing of conveyed quantities

- High throughput due to fast and WM approved processing of measuring values

- Dynamic incline compensation for movable belts

- Universal use with a variety of scale designs

- Suitable for harsh environments and outdoor use (NEMA 4X / IP65 / IP69K)

- Simple system integration (connection to PLCs via fieldbus or Modbus TCP, Ethernet, wireless LAN, printer interface, etc.)

- Powerful PID controller to control the flow rate

Typical fields of application

Beltweighers are suitable for all bulk material handling industries, e.g.

- for the building material

- food sector

- feeding stuff

- chemical and pharmaceutical industries

- plastics

More: interview on belt scales

In this interview, SysTec seminar leader Ivo Mewes explains the special features of belt weighers and suitable weighing electronics. He also answers questions on calibration and different customer requirements.

| Model | IT2000M BELT | IT3 BELT | IT6000E BELT | IT8000E BELT |

|---|---|---|---|---|

| Display of feed rate / feed quantity | - | |||

| W&M approved | - | |||

| Batch mode | ||||

| Analog output | ||||

| Modbus/TCP | ||||

| PROFIBUS DP / PROFINET / Ethernet/IP | - | |||

| Continuous output | - | |||

| Remote control serially | - | - | - | |

| Protocol print | - | |||

| Protocol file | - | - | ||

| Exactly positioned zero point | - | - | ||

| Dynamic inclination compensation | - | - | ||

| Feedback control of feed rate / load | - | - | ||

| Custom-specific modifications | - | - | ||

| Alphanumeric keyboard | - | - | - |