Accuracy classes for scales: Combination of different types of scales in classes of equal accuracy. According to the international guidelines of the EC there is the following classification: coarse scale = class (IIII), commercial scale = class (III), precision scale = class (II), fine scale = class (I).

Weight storage for scales requiring W&M approval that evaluate and process the weighing data via a connected EDP system. Electronic archiving by means of a data storage device that conforms to guidelines and cannot be manipulated is required. All data transmitted to the computer (such as date, time, weight) are stored for at least three months.

Animal scales are used in agriculture, in veterinary medicine as well as in zoos. They can be designed as mobile single animal scales, floor scales and group animal scales. Digital weighing indicators display weight values and provide interfaces to other systems (e.g., for data processing and storage). Animal scales are equipped with special filter options and animal weighing programs. These provide stable and accurate measurement results, even when animals move on the scale and generate vibrations. Robust and easy-to-clean materials such as stainless steel are used for the weighing electronics. SysTec weighing terminals have proven themselves in various livestock scales.

Abbreviation for ATmosphères EXplosibles. The ATEX directive regulates the use of equipment and components in potentially explosive industrial environments within the EC. Explosion hazards can be caused by flammable substances such as gas, steam, mist or dust.

- More regarding ATEX weight indicators

AWI: Scales where the weighing process is carried out without interaction of the operating personnel.

A distinction is made between:

- Automatic gravimetric filling instruments (AGFI)

- Automaticdiscontinuoustotalizers (bulk weighers)

- Automatic continuous totalizing weighing machines (conceyor belt weighers)

- Automatic checkweighing instruments (checkweighers)

- Automatic railroad scales

Axle weighers or axle load scales are used to determine the axle load of a vehicle. In order to ensure safe transports, a balanced weight distribution on the individual axles of a vehicle is important. Unacceptable overloading of trucks and other vehicles can be avoided with axle load scales and wheel load scales, so that no fines are incurred. Axle load scales belong to the category of truck scales / vehicle scales.

- More regarding vehicle scales

Bagging systems or bagging scales are used for filling bags between 10 and 50 kg. Solids are filled into open bags or valve bags. The accuracy, the filling speed and the control of the filling process play a central role.

Large containers (IBCs) are filled with BigBag scales (the filling quantities are usually between 300 kg and 1500 kg). BigBag scales can be designed in a simple version with manual handling or as fully automated systems.

- More regarding bagging & filling systems

Batch controllers are designed for ... read more

A belt scale is usually installed ... read more

Automatic weighing instrument - read more

Check scales are used to monitor production goods according to weight criteria. A distinction is made between static and dynamic check scales (checkweighers). For static weight checks often plus-minus scales are used.

Automatic check scale for... read more

Combination of scales with ... read more

Conformity assessment is required when a weighing instrument is first put into circulation. It confirms the conformity of the weighing instrument with the requirements of the applicable directives and their implementation in national law (Verification Act). The conformity assessment can be carried out by the W&M authorities as well as by many manufacturers and distributors. Conformity-assessed scales are marked with a CE mark and the respective year as well as the number of the type examination certificate, the assessment certificate or, if applicable, only the approval number.

The German Accreditation Body (DAkkS) is, among others, the successor organization of the German Calibration Service (DKD). A European regulation required the EC member states to establish a single national accreditation body and thus various German predecessor organizations merged to form the DAkkS in 2010. Besides the DKD, these were the German Accreditation Body Chemistry (DACH), the German Accreditation System for Testing (DAP) and the German Association for Accreditation (TGA), to which also the German Accreditation Body Technology (DATech) belonged.

Electronic weighing terminal for digital display of weight values in a specific weight unit... read more

The guideline regulates the putting into circulation and the general requirements such as measurement deviation/classification of 'automatic weighing instruments'.

The technical requirements / tests are governed by the following guidelines:

- OIML R61 (AGFI) = Automatic gravimetric filling instrument

- OIML R51 = Automatic catchweighing instrument

- OIML R51 = Automatic checkweighing instrument

- OIML R107 = Automatic discontinuous totalizer

Evaluating instruments display, among other things, weight values in a certain weight unit. For this purpose they convert the digital signal received from load receptors / load cells into a suitable value. Thus, the evaluating instruments / weighing indicators can show the determined weight on a display, but also transfer it via an interface and perform additional control functions.

Fieldbus is the generic term for various physically distinct bus systems for automation, production engineering, building automation and automotive technology. There are wired or wireless bus systems with which field devices (sensors and actuators) are connected to the control devices and SCADA systems and which execute the fast data exchange between the individual components.

Filling systems

Filling scale for liquids (in ATEX zone)Filling scales are automatic scales and are usually subject to the regulations of the corresponding national laws (verification act), as they are used in commercial transactions. The product to be weighed is automatically fed to the scale. Weighing and filling of the product must usually be done quickly (during the filling process).

- More regarding filling systems

Hopper scales play an important role in weight and level determination in trade, production, industry and agriculture. Hopper scales consist of load cells and weighing indicators on which the weight value is displayed. In trade, the verification capability of the weighing electronics is crucial.

The contents of the container can be bulk goods, liquids or gases, for example. Hopper scales are available in various designs. In upright hopper scales, the load cells are attached to the leveling feet. Tension weighing modules are used for suspended installed hoppers.

Information about the ingress protection of housings against dust and water.

- IP65 (according to DIN EN 60529): Suitable for short-term contact with a liquid. Dust-tight.

- IP67 (according to DIN EN 60529): Suitable for short-term use in wet areas. Immersion possible. Dust-tight.

- IP68 (according to DIN EN 60529): Suitable for permanent use in wet areas. Submersion possible. Dust-tight.

- IP69K (according to DIN EN 40050): Completely tight and thus protection of the electrical equipment against penetration of solids and dust. Protection against the ingress of water during high-pressure or steam-jet cleaning

The basis of every scale and weighing system is the load cell. Load cells are used to measure force or weight, respectively. Like most types of force transducers, load cells usually contain a spring body (counterforce), i.e. a shaped piece of (mostly) metal whose geometry changes slightly under the influence of weight. This elastic deformation is detected by strain gauges for weights from a few grams up to several 1000 tons and converted into an electrical signal.

According to the EC Directive 90/384/EC, scales must be officially verified if, for example, they are used as follows:

- Business transactions, when the price of a good is determined by weighing.

- Manufacturing of pharmaceuticals in pharmacies and for analyses in medical and pharmaceutical laboratories.

- For official purposes.

- In the manufacturing of prepackaged goods.

Outside the EC, country-specific regulations apply to mandatory verification.

Parts counting scales

Parts counting scalesParts counting scales, also simply called counting scales, are used for inventory, quantity checks and order picking. They ensure fast and precise determination of parts counts and/or parts weights. For this purpose, the piece counting scales divide the weight by reference weight (piece count) or by the set or determined number of pieces (piece weight).

Process scales are usually scales integrated into a production process. Their function is not standardized because they have to be adapted to the corresponding production process and production conditions.

All planned and systematic activities necessary to provide reasonable confidence that a product or service will meet certain quality requirements ([ISO 9000] 3.2.11). These quality requirements may be defined by the manufacturer of a product himself or may be specified in standards or other normative documents.

Silo scales are used for weight determination - read more

SQC weight indicator

SQC weight indicatorAbbr. for 'statistical quality control'. More on SQC

Static scale: There is no relative movement between - read more

(1 Autotare) Feature to reset the weight display of a (partial) weight (e.g. container) standing on the weighing platform to zero by pressing the tare-key. Can be repeated as often as required for electronic scales.

(2 Manual tare) Feature to subtract a tare weight from the weight display by entering a tare weight.

The suitability for use in applications requiring W&M approval of a weighing instrument or weighing terminal is documented by the type approval of a Notified Body. For this purpose, the scales or weighing terminals are subjected to a verification test. Conformity to applicable standards in the EC and/or other countries, e.g. OIML, WELMEC, NTEP, Measurement Canada, NMI, etc. is reviewed. This includes both metrological and device-specific requirements. The type approval is documented with the type approval certificate.

A vehicle body scale is a non-automatic scale for weighing the load of commercial vehicles, e.g. garbage trucks. For this purpose load receptors / load cells are installed between the chassis and the body of the vehicle. The influence of the inclination of the vehicle on the weighing is compensated by means of an inclination sensor.

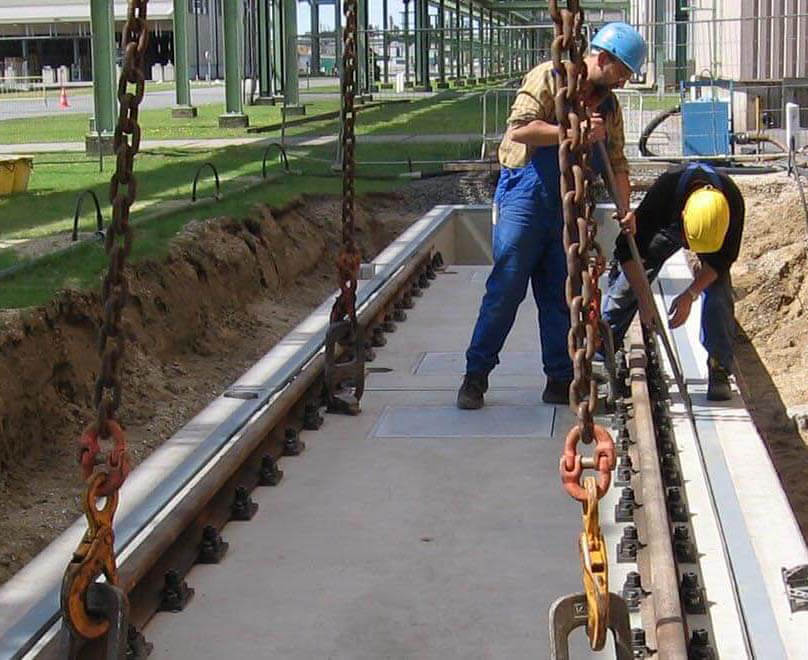

Vehicle scale / truck scale

Vehicle scale / truck scaleTruck scales enable the determination of individual vehicle weights, net weights of the vehicle load and overloading checks. There are different types of scales: stationary, mobile, floor- or pit-mounted, in all-steel or concrete design.

Volumetric dispensers deliver a certain volume of material per time unit. The volumetric measurement is based on known volume units of a specific material, which is transferred to a derived mass-based discharge using sampled calibration. Feed rate changes are accomplished by adjusting the feed rate (e.g. speed of screw feeder).

Determination of the mass or weight, respectively, of a sample. Weighing can be static or dynamic.

Static: No relative movement between the sample and the load receptor during weighing. A static weighing is always discontinuous.

Dynamic: Relative movement between the sample and the load carrier during weighing.

Weighing indicators for industrial scales (also called weighing terminal, weight indicator or scale display)

Weighing indicators for industrial scales (also called weighing terminal, weight indicator or scale display)Weighing indicators (also weighing terminals or scale displays) show, among other things, weighed values in a certain weight unit. For this purpose they convert the digital signal received from load cells into a desired signal. Thus, the weighing indicators can show the determined weight on a display, but they also convert the digital signals into control signals via appropriate interfaces.

Abbreviation for 'European Cooperation in Legal Metrology'. When the organization was founded, WELMEC stood for 'Western European Legal Metrology Cooperation'. Among other things, the cooperation promotes the exchange of information, the uniform application of European or international regulations, the elimination of trade barriers for measuring instruments and it records special aspects of legal metrology. For these purposes, WELMEC issues recommendations, the so-called 'WELMEC Guidelines', and maintains working relations with national and international bodies.

In addition to the 30 member states of the European Union and the European Free Trade Association (excluding Liechtenstein), WELMEC also includes Turkey and Croatia as associate members. There are also several observing and corresponding organizations, including the 'International Organization of Legal Metrology' OIML.

Wheel load scales are used to determine - read more