SysTec weighing terminals for bucket filling line

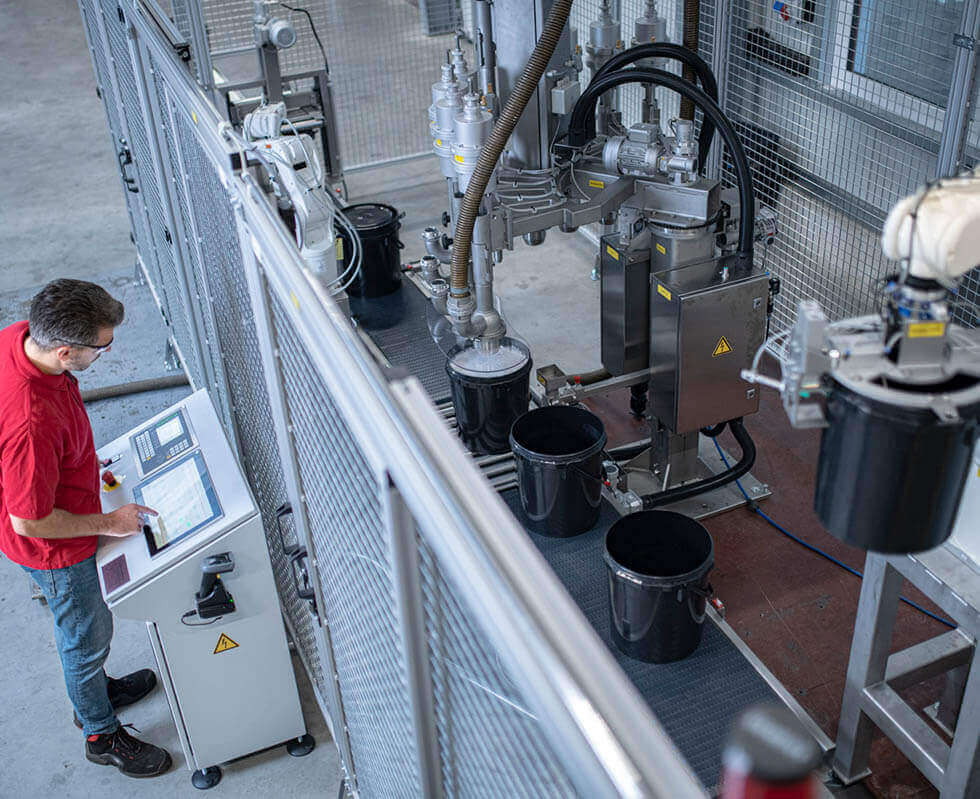

At the Hilti site in Kaufering, Germany, SysTec‘s partner KESTERMANN GmbH recently installed a fully automated filling system for the W&M approved filling of buckets with robot handling. A fire protection paste is filled into containers of different sizes - quickly, precisely and efficiently. SysTec’s powerful IT8000E weighing terminals in combination with the FILL E application software ensure a high throughput.

The key facts

- Automatic weighing instrument (AWI) for filling of buckets

- W&M approved filling of liquids

- Robust weighing electronics

- PROFINET connection

- Fast filling of containers with different sizes (5, 10, 15 and 20 liters)

Products

- IT8000E: Versatile and robust SysTec weighing terminal for continuous operation

- SysTec application software FILL E ensures rapid filling – customized software modifications

- Powerful KESTERMANN filling system incl. installation and service

PDF Download

Case study: Filling line with SysTec weighing electronics

The end user - Hilti

The Hilti Group supplies the construction and energy industries worldwide with technologically advanced products, system solutions, software and services. With around 31,000 employees in over 120 countries, the company is a global player. Since its founding in 1941, the headquarter of the Hilti Group is located in Schaan, Liechtenstein.

The material: fire protection paste

Hilti Fire Protection Paste is used for the permanent sealing of cables and cable trays, as well as combustible and non-combustible pipes in medium to large wall and ceiling openings.

The highly flexible coating dries quickly to form an elastic protective layer and is smoke-tight.

Efficient throughput

Buckets of different sizes are filled in the plant: 5, 10, 15 and 20 liters. The throughput differs according to the different sizes of the containers. For example, 280 buckets of 5-liter size can be filled per hour. When the large 20-liter buckets are used, the system handles 220 per hour.

The process

A multi-stage and fully automated process takes place during the filling of the buckets: First, the product code is scanned by a supervisor. The filling parameters are stored in the IT8000E weighing terminal and the automated filling process can start:

At the first station, a robot takes over the destacking of the buckets. They are then transported on a conveyor belt to the weighing station, where a filling system fills the buckets. Here, the SysTec weighing electronics ensure precise and fast filling of the fire protection paste into the containers. In the next step, a foil is applied to the bucket. Then a robot places the bucket lid on the filled bucket. At the last station, the lid is pressed firmly onto the bucket by a press-on device and sealed. Among the advantages of the SysTec weighing systems with W&M approval are the PROFINET connection, the robustness of the weighing electronics and the product-specific parameter settings.

Weighing terminal IT8000E

- High ease of use: simple multilingual operator prompting, bright 5.7“ TFT color display with wide viewing angle and large-character weight display, alphanumeric keyboard

- W&M approved use as non-automatic and automatic weighing instrument possible (approved in the EC, USA, Canada, etc.)

- Universal use: numerous standard application programs available

- Customizable: free programmability

- Robust: stainless steel housing (ingress protection IP69K)

- Ex-area: for hazardous areas SysTec offers the version IT8000E Ex2/22 and for zones 1/21 the IT8000Ex unit

- Various designs: wall-mount / desk-top version as well as panel-mount version

- Connection options: in relation to FILL E applications: connectable are 1 or 2 scales of different types with analog or digital load cells. Connection options for IT8000E in general: 2 internal and up to 6 external scale connections, can be integrated into PC networks via Ethernet or WLAN, connection to label printers and network printers, PLC connection via fieldbus

- High operational security: data storage power-fail safe, password protection, battery-backed real-time clock, remote diagnostics possible via Internet

![[[Translate to "English"]] Kestermann [[Translate to "English"]] Kestermann](/fileadmin/public/Redaktion/Bilder/Content/Filling-Station-Buckets/dominik-kestermann.jpg)

"We have a long-standing partnership with SysTec. We appreciate the great variety of SysTec weighing terminals. There are numerous ready-made application programs for the most diverse areas of use. In addition, special customer requirements can be easily implemented thanks to the free programmability of the weighing terminals."

Dominik Kestermann, Project Engineering & Sales, KESTERMANN GmbH